Oct 1,2024

Processing food efficiently, precisely, and consistently is of the utmost importance. The equipment utilized is essential in every kitchen, whether a little artisanal or a massive industrial one. The bowl cutter machine is one example of a piece of technology that has significantly advanced food preparation.

This multipurpose device is used for anything from chopping meat and poultry to chopping veggies and even dough. Explore the inner workings of a bowl cutter machine, its many uses, and the advantages it provides to the food sector in this in-depth study.

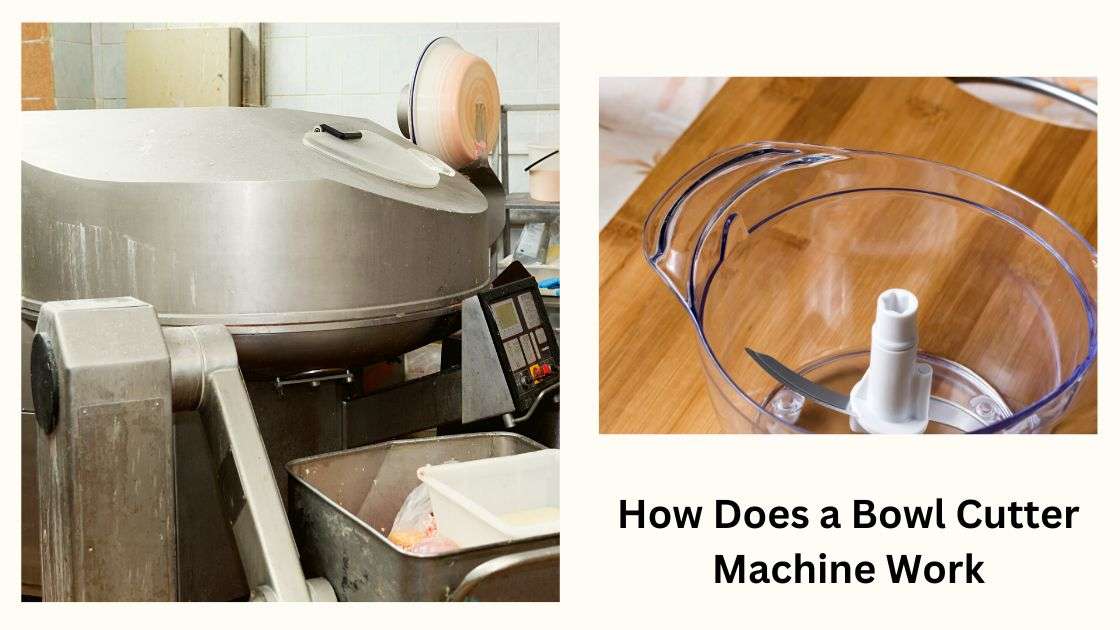

Bowl cutter machines, also known as bowl choppers or food choppers, are kitchen appliances used for chopping, blending, and emulsifying a wide variety of foodstuffs in a bowl-shaped mixing basin.

These appliances are a must-have in any establishment that prepares large quantities of food, such as a restaurant, catering company, or factory. Their primary purpose is to lessen the amount of manual effort and time spent on meal preparation without sacrificing quality.

A typical bowl cutter machine consists of the following main parts: a circular bowl or container, a cutting assembly with several sharp blades, a motor for powering the device, and a control panel for modifying settings and operating the machine.

These machines range from little models well-suited to home use to enormous factory behemoths that can process vast quantities of food in a single cycle, each with unique advantages and disadvantages.

It is necessary to dissect the workings of a bowl cutter machine in order to grasp how it functions fully.

The machine's bowl is where the processed food components begin their journey. While the exact size and shape of the components used for a given job can vary, it's common practice to break them up into smaller pieces to ensure uniform processing.

The components are kept confined throughout the procedure by locking the circular bowl into place. Safety interlock systems are standard on modern bowl cutter machines, preventing operation until the bowl is in place.

The operator may alter parameters like the machine's processing time and blade rotation speed before turning on the device. The details of these controls will vary with the task at hand and the raw materials being used.

After adjusting the machine's parameters, the operator presses the "start" button to engage the machine's robust motor. The blades within the bowl may be rotated by this motor, which provides the required rotational force.

The blades spin, touching whatever's in the bowl as they go. The sharp blades quickly and easily reduce the components to uniformly sized bits. The mixing and blending effect created by the rotating and cutting movement ensures that flavors and textures are distributed uniformly.

When cutting meat, for example, specific bowl cutter machines have the capacity to emulsify components. This implies that the machine can thoroughly combine different ingredients like lipids and proteins

Throughout the process, the operator looks through a glass or periodically stops the machine to make sure the mixture has the right consistency. If required, tweaks may be made.

After the food has been processed, the machine will automatically shut off, and the bowl will be unlocked and able to be removed. Your final product is uniform in texture and consistency, suitable for additional processing or cooking.

Various sectors of the food processing industry make use of bowl cutter machines. The most common applications are:

Bowl cutters are an essential tool in the meat industry, where they are used to mincemeat, mix different types of meat, and make uniform fillings for sausages and meatballs. The smooth texture of pâtés and spreads is achieved by emulsifying fats and proteins with them.

Bowl cutter machines are used to chop, slice, and combine vegetables in industrial kitchens and catering businesses. Salads, coleslaw, and other mixed vegetable meals benefit greatly from their usage in creating consistent portions.

Bakeries utilize bowl cutter machines to cut dough for items like bread, pastries, and pizza. They ensure the dough has the same texture and the ingredients are well-mixed.

Mayonnaise, pesto, and aioli are just a few examples of the many condiments and sauces that need careful blending and emulsification before serving. Emulsions may be made smoothly and reliably with the help of bowl cutters.

These devices are used in the dairy industry to aid in the processing of yogurt and ice cream, both of which are made from milk. Curds are sliced and mixed with them during the cheesemaking process.

Pastry and confectionary makers utilize bowl cutters to prepare their components. Nuts, fruits, and other ingredients may be combined and chopped to be used in a wide range of baked goods.

For example, you may know almond butter and peanut butter are made by crushing nuts into a paste. The use of bowl cutters is essential.

Large quantities of salad dressings, marinades, and vinaigrettes may be made uniformly by using this equipment in the food service business.

Bowl cutter machines have seen extensive use in the food sector due to their many advantages.

Bowl cutter machines greatly alleviate the need for laborious hand cutting. Vegetable chopping, for example, is a time-consuming chore that may be finished in a few minutes with one of these machines.

The degree of uniformity these machines provide is difficult to attain by hand. This uniformity is essential for the safety and appeal of food items.

Bowl cutters are useful because they cut and mix components, resulting in a more uniform flavor and texture in the finished product. For instance, this leads to a more consistent blend in the meat processing sector.

Bowl cutter machines prioritize food hygiene in their construction. The components are often made of stainless steel, which is both durable and simple to clean. These devices also mitigate injuries from chopping and cutting by hand.

These appliances have a wide variety of applications in the food industry. Their versatility makes them essential in many kitchens, where they are used to process anything from meats and vegetables to bread and cheese.

Bowl cutter machines require a significant upfront investment from many food service establishments, but in the long run, they save money via reduced labor costs and greater output.

Food manufacturers may easily cater to individual diners' tastes by adjusting the settings on several types of bowl cutter machines.

Some uses greatly benefit from emulsifying fats and proteins, such as banger manufacturing and the production of silky, creamy substances.

As a result of its ability to facilitate the rapid and uniform cutting of a broad range of food items, bowl cutter machines have become an absolute need in today's food processing facilities. These appliances are highly sought after in institutional kitchens, catering businesses, and industrial food processing plants because of their speed, accuracy, and adaptability. Bowl cutter machines are anticipated to play a more critical role in the future of the food sector, helping to maintain high standards for the foods we consume. Knowing how these machines function and adhering to safety protocols allows operators to maximize their usefulness in the food industry.